TECHNICAL ADVICE

The Ultimate Guide to Glass Types for Modern Architectural Glazing

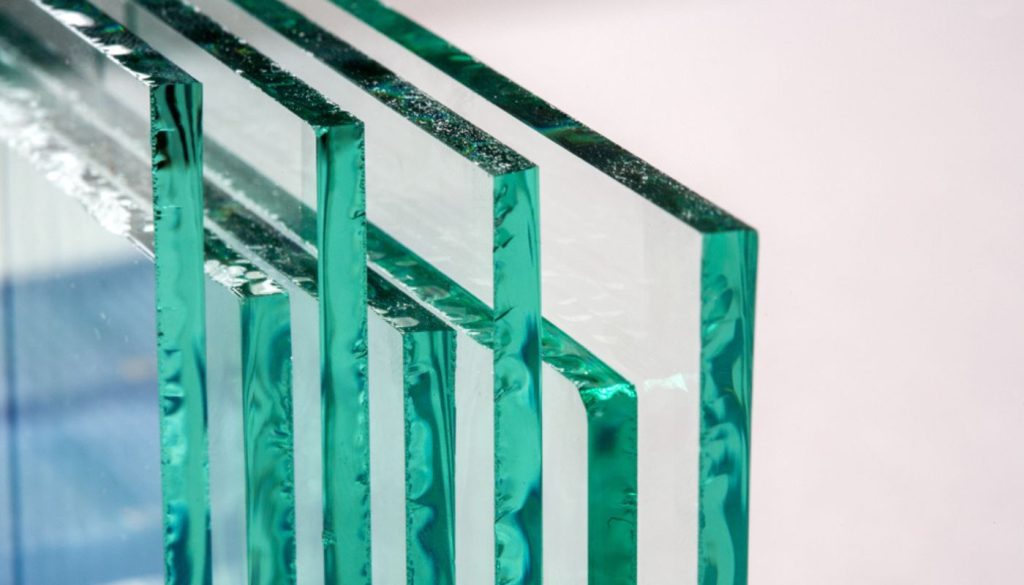

Modern architecture thrives on glass – its clarity, structural possibilities and ability to merge interior and exterior spaces make it integral to today’s building envelopes. However, the sheer variety of architectural glass types can be overwhelming. Float glass, low-iron glass, low-e coatings, laminated interlayers and more; each offers unique performance characteristics essential for design success. In this guide, we cover the main types of architectural glass, explore how they’re manufactured and highlight where each specification excels. Whether you’re designing a minimalist curtain wall, a frameless balustrade or making a statement with a glass draught lobby, this guide will help you choose the right solution and understand the nuances that matter.

Float Glass: The Foundation of Architectural Glazing

What is Float Glass?

Architectural glass typically starts as float glass before further treatment. At Sieger Systems, we enhance these base panes with lamination, toughening, heat-soaking and/or specialty coatings to meet modern safety and performance standards. Formed by floating molten glass on a bed of molten metal (commonly tin), the float glass production process yields a smooth surface and a uniform thickness.

Key Attributes

- Uniform Thickness

- The ‘raw’ substrate; basic glazing for further treatment

- High Clarity (in thinner panes)

- Float glass is relatively neutral in appearance but can develop a subtle greenish tint in thicker panes.

- Base for Other Treatments

- Tinted, toughened, laminated or coated glass all typically originate from float glass.

Low-Iron Glass: When Colour Fidelity Matters

Why Low-Iron?

In terms of architectural glass types, ‘colour fidelity’ refers to how accurately the glass preserves or transmits the real colours of objects or surroundings. A common challenge with standard float glass is the green tint noticeable in thicker applications (e.g. multi-laminated balustrades, exposed edges or glass floors). Low-iron glass reduces the iron oxide content to enhance transparency and colour neutrality.

Ideal Applications

- Balustrades and Frameless Railings

- Visible edges remain crystal-clear.

- Floorlights and Roof Glazing

- Thick, multi-layer units benefit from improved clarity.

- Decorative Installations: Coloured interlayers or surface treatments show truer hues.

Cost and Considerations

- Premium Price

- Additional manufacturing steps often lead to a higher cost.

- Highly Recommended for Exposed Edges

- Especially in thicker or multi-layer applications.

Relevant In-Depth Reading

- For understanding how reducing iron content in standard float glass results in even higher clarity.

Low-E (Low Emissivity) Glass: Optimising Thermal Performance

What is Low-E Glass?

Low-E glass features a microscopically thin, transparent coating (often metallic oxide) on one or more surfaces within a double or triple-glazed unit. This coating reduces the glass’ emissivity, reflecting thermal radiation and thereby improving insulation.

Thermal Benefits

- Reflects Interior Heat

- Helps maintain warmer indoor environments in colder climates.

- Controls Solar Gain

- Keeps interiors cooler in hot climates, reflecting external heat.

- Reduces Energy Bills

- Minimises the load on HVAC systems.

Additional Advantages

- UV Protection

- Some coatings help block harmful rays, preserving furnishings and flooring.

- Versatile Combinations

- Low-E coatings can be paired with tinted or laminated glass for even higher performance.

Further Reading

- For a deeper dive into emissivity ratings and the science behind thermal reflection.

Toughened (Tempered) Glass: Safety Through Strength

Toughened glass is essentially safety glass. It’s widely used in the UK, because it’s required for Part K Building Regulations. Toughened glass is produced by heating float glass to around 650–700°C and rapidly cooling it. This creates a compressive exterior layer balanced by tensile stresses inside the glass, boosting its strength.

Safety Features

- Shatters into Small Particles

- When fractured, it breaks into small, blunt fragments, reducing risk of severe injury.

- Up to Five Times Stronger

- Compared to standard annealed glass types, it can withstand greater impacts and temperature changes.

Heat Soaking

- Extra Step to Prevent Spontaneous Breakage

- Heat soaking helps weed out panes susceptible to nickel sulphide inclusions.

- Important for Structural, Hard-to-Access or Frameless Installations

- Though rare, spontaneous breakages are more critical to avoid in balustrades, rooflights or extensive façades.

Recommended Reading

- For a thorough explanation of why some projects might require that additional heat-soak test.

Laminated Glass: Strength and Security in Layers

How it Works

Laminated glass comprises two or more layers of glass bonded by an interlayer (e.g., PVB or SGP). Under impact, the glass may crack but largely remains adhered to the interlayer, improving safety and security.

Applications

- Balustrades, Structural Glass Walls, Rooflights, and Floors

- Multiple layers plus an interlayer create high load resistance.

- Acoustic Control

- Can significantly dampen external noise.

- UV Protection

- Many interlayers block up to 99% of UV rays.

Interlayer Choices

- PVB (Poly Vinyl Butyral)

- Traditional, offers good security and UV blockage but can degrade if exposed to moisture on edges.

- SGP (SentryGlas Plus)

- Ionoplast interlayer with five times the strength and 100 times the rigidity of PVB. Ideal for exterior frameless systems.

Design Options

- Coloured Interlayers

- Achieve brand colours or design statements.

- Printed Interlayers

- Incorporate logos, patterns or custom graphics for unique features.

- Fabric Inclusions

- Textures and fabrics can be sandwiched for decorative effects.

Learn More

Heat-Strengthened Glass: A Middle Ground

What is It?

Heat-strengthened glass is partially toughened. It undergoes a similar heating and cooling cycle but not as extreme, yielding a pane about twice as strong as annealed glass (but weaker than fully toughened).

Why Specify It?

- Reduced Risk of Spontaneous Breakage

- Lower internal stress than fully toughened glass types.

- Less Fragmentation

- In the event of breakage, shards tend to be larger than toughened shards, but they still hold together better than annealed.

Tinted, Reflective and Decorative Glass Types

Tinted Glass Types

During manufacturing, mineral additives create a coloured hue (bronze, grey, green, etc.). This reduces glare and solar heat gain, making it useful for exposed façades.

Reflective & Low-Reflectivity Coatings

- Reflective

- A thin metal oxide layer (often aluminium) provides a mirror-like exterior that can assist in managing solar gain.

- Anti-Reflective Coatings

- Useful for shopfronts and display glazing where clarity is paramount and reflections are undesirable.

Textured & Patterned Glass Types

- Privacy and Light

- Allows natural light while preserving privacy; ideal for office partitions, bathrooms or decorative features.

- Variety of Patterns

- From reeded textures to frosted designs.

Specialty Decorative Glass Types

- Cast Glass

- Molten glass poured into a mould, offering a variety of shapes and surface finishes.

- Fused Glass

- Multiple layers heated until they bond, often used for artistic or bespoke architectural applications.

- Holographic and Dichroic Glass

- Enhanced reflectivity and colour shifting for eye-catching features in retail or hospitality contexts.

Insulated Glass Units (IGUs): Balancing Efficiency and Comfort

Composition

IGUs combine two or more glass panes separated by a spacer, with air or an inert gas (e.g., argon) sealed between them. This structure forms a thermally efficient barrier.

Energy and Acoustic Benefits

- Reduced U-Values

- Minimises heat transfer, lowering energy costs and improving occupant comfort.

- Condensation Control

- Properly sealed units help manage moisture and prevent fogging.

Enhancements

- Low-E Coatings

- Further improve insulation when applied to the inner surfaces of IGUs.

- Triple Glazing

- Additional pane plus another layer of gas for stricter energy codes or harsh climates.

Structural Glazing Essentials

For architects looking to minimise frames and maximise transparency, structural glazing systems—such as frameless walls, glass draught lobbies or glass beams and fins—are often the go-to. These advanced assemblies typically require:

- Heat-Soaked, Toughened and Laminated Glass for maximum safety and structural stability.

- SGP Interlayers for edge-exposed or high-load scenarios.

- Low-Iron Substrates to maintain true colour and avoid green tints in thicker glass or multi-laminations.

Choosing the Right Glass for Your Project

With countless combinations of coatings, interlayers, thicknesses and treatments, specifying glass types can feel daunting. Here’s a simplified approach:

Assess Performance Needs

- Thermal Efficiency

- Consider Low-E or insulated units for external façades.

- Safety & Security

- Use laminated glass in high-risk areas, such as balustrades, floors and overhead installations.

- Structural Requirements

- Evaluate load-bearing aspects (heat-soaked, toughened or even triple-laminated in some cases).

Evaluate Aesthetics

- Optical Clarity

- Low-iron glass for minimal colour distortion.

- Decorative Coatings or Interlayers

- Tints, printed films or specialised textures.

- Frameless or Minimalist Look

- Pay close attention to edge finishes and interlayer clarity (especially in externally exposed edges).

Consider Longevity and Maintenance

- Weather Exposure

- For external, frameless systems, consider SGP interlayers to avoid moisture infiltration.

- Location & Replacement Complexity

- Hard-to-access areas may warrant heat-soaked glass to reduce the minute risk of spontaneous breakage.

Budget and Project Constraints

- Cost vs. Benefit

- Heat-soaked SGP-laminated low-iron glass can become pricey, but may be justified by the performance and aesthetic payoff in high-end architectural works.

Dive Deeper With Our Articles

We’ve prepared in-depth resources for you to explore each glass topic further. Our technical team at Sieger Systems has published detailed articles on:

These comprehensive guides walk you through real-world project examples in terms of glass types, from frameless balustrades to thermally broken floorlights, so you can see how the right glass specification translates into practical, elegant design solutions.

Let Us Help You…

Architectural glass continues to evolve, bridging form and function in cutting-edge building envelopes – from expansive skylights that bathe interiors in daylight to secure glass draught lobbies that keep the elements at bay without sacrificing transparency. Understanding the technical details behind each glass type is a key step toward selecting the optimal specification for longevity, safety and beauty.

Now you’re ready for personalised guidance about a unique design challenge,

Contact Us Now!

RELATED CASE STUDIES

Case Studies